.webp)

Easy to Use

Thanks to its ergonomic design and user-friendly interface, it reduces the workload of operators and offers ease of use.

.webp)

Maliyet Tasarrufu

Vertical press machine provides cost advantage to businesses with its energy efficiency and effectiveness in waste management. Although vertical bale press machine prices vary according to capacity and features, it provides savings in the long term.

.webp)

Security Features

It is equipped with various safety systems for user safety. It provides a safe working environment with PLC controlled models and manual valve options.

.webp)

Durability and Longevity

The vertical baling press machine is manufactured from high-quality materials and provides trouble-free operation for many years with its durable structure.

.webp)

Yer Tasarrufu

The vertical press machine saves space even in businesses with limited space thanks to its vertical structure. This feature offers efficient use especially in small areas.

.webp)

Compacting Various Types of Waste

The vertical baling press machine can effectively compress paper, cardboard, plastic, nylon and many other recyclable materials, thus offering versatile use.

.webp)

High Efficiency

The vertical press quickly turns large quantities of waste into bales with its fast compression cycles. This ensures speed and efficiency in the production and recycling processes.

.webp)

Reducing Waste Volume

The vertical bale press reduces waste volume by up to 90%, providing significant savings in storage and transportation costs. Compressed bales take up less space and create lower transportation costs.

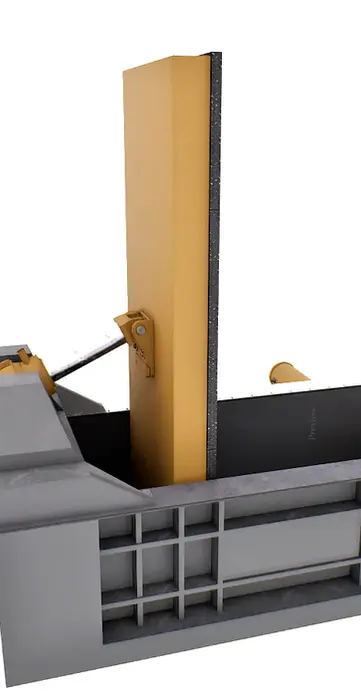

Vertical Baler, Innovative Solutions in Waste Management

The vertical bale press is an innovative solution for waste management in industrial and commercial sectors. The vertical bale press significantly reduces waste volume, reducing storage and transportation costs, while making recycling processes more efficient. The vertical bale press produces compact bales by compressing various waste materials such as paper, cardboard, nylon, plastic with high pressure, which makes waste management more effective.

The vertical bale press machine offers an effective solution by saving space even in businesses with limited space. The hydraulically operated vertical bale press machine allows waste materials to be easily placed in the machine thanks to its wide feeding mouth. It turns waste into bales with a powerful compression mechanism and can reduce waste volume by up to 75%.

Vertical press can be easily used in every sector with its user-friendly structure. Vertical bale press machine prices may vary depending on the capacity and features of the model. Vertical press machine offers long-lasting use with its durable structure and energy efficiency, which saves businesses money.

The vertical baler press supports environmental sustainability by providing efficiency in waste management in recycling processes. The machine vertical press offers a powerful solution for businesses in terms of reducing waste volume, reducing costs and minimizing environmental impact.

Vertical Baling Press Advantages: Cost and Space Savings

The vertical bale press reduces waste volume by up to 90% with its high compression capacity, providing great savings in storage and transportation costs. Thanks to the vertical bale press, large amounts of waste are baled in a short time with fast compression cycles. The wide feed opening and holding claws ensure that waste materials are easily fed into the machine and compressed quickly.

The vertical press reduces the workload of users and increases productivity thanks to its ergonomic design. The vertical baling press machine is equipped with various safety features for user safety and provides safe and controlled operation with PLC controlled or manual valve options. The vertical baling press, manufactured from high quality materials, stands out with its long-lasting and durable structure.

Vertical baling press machine is capable of compressing paper, cardboard, nylon, plastic and other recyclable materials. It meets the needs of various industries with its flexibility to produce bales of different capacities. The machine vertical press offers an environmentally friendly solution with its energy efficiency, low energy consumption and low noise level, optimizing the working environment.

Vertical bale press machine prices vary depending on the capacity and features of the model, but in the long run, it offers great advantages to businesses by providing cost savings. The vertical press machine stands out as an environmentally friendly and efficient solution in waste management.

Reduce Storage and Transportation Costs with a Vertical Baler

Vertical Baler Press Performance and Efficiency

Reducing Waste Volume

The vertical bale press reduces waste volume by up to 90%, providing significant savings in storage and transportation costs. Compressed bales take up less space and create lower transportation costs.

High Efficiency

The vertical press quickly turns large quantities of waste into bales with its fast compression cycles. This ensures speed and efficiency in the production and recycling processes.

.webp)

Durability and Longevity

The vertical baling press machine is manufactured from high-quality materials and provides trouble-free operation for many years with its durable structure.

.webp)

Security Features

It is equipped with various safety systems for user safety. It provides a safe working environment with PLC controlled models and manual valve options.

The vertical baling press is an ideal solution for baling high volumes of recyclable materials in recycling facilities. Effective compression of paper, cardboard, plastic and other materials speeds up recycling processes and reduces costs. The vertical press is used in large factories to compress and store waste generated during production processes, which provides a great advantage in waste management.

Vertical bale press machine can be used in waste sorting facilities to separate mixed waste and turn it into bales, which reduces waste management and recycling costs. Vertical press machine optimizes waste management processes in supermarkets, logistics companies and large storage areas. It makes logistics processes efficient by facilitating the storage and transportation of waste materials.

Machine vertical press offers flexible solutions for waste management in different sectors. Although vertical bale press machine prices vary according to capacity and features, they provide cost savings to businesses in the long run. Offering high performance in waste compression, the vertical baler press stands out as a strong solution in environmental sustainability and waste management.

Vertical Bale Press Usage Areas:

.webp)

Vertical Bale Press Technical Specifications

Ürün | Balya (mm) | Ağırlık (kg) | Motor (kw) |

|---|---|---|---|

DB-120 | 1200 X 1100 X 1100 | 800-1200 | 75 |

DB-50 | 1200 X 1500 X 1100 | 250-300 | 11 |

DB-20 | 1000 X 975 X 800 | 130-150 | 3 |

DB-5 | 600 X 435 X 560 | 40-45 | 1,5 |

DB-10 | 735 X 700 X 500 | 60-75 | 2,2 |

DB-15 | 850 X 900 X 800 | 90-100 | 2,2 |

Optional Features

PLC Control System

Remote control

Double Piston Compression System

Cycle Time Monitoring

Mobile Unit Options

Security Cages and Light Curtains

Vertical Baler Frequently Asked Questions (FAQ)

The vertical baling press is a machine that compresses various waste materials into compact bales. These bales make storage and transportation processes more efficient. Thanks to its vertical structure, it can be used effectively even in businesses with limited space.

Our vertical baling presses can compress and bale paper, cardboard, nylon, plastic, textiles and many other recyclable materials. These machines have the capacity to process different types of waste.

Our vertical bale press machines work with hydraulic systems. Waste materials are placed into the machine through the wide feed opening and are compressed under high pressure with a powerful hydraulic press system and turned into bales.

In recycling facilities, in baling high volume recyclable materials. In large factories, in compressing and storing waste generated in production processes. In garbage sorting lines, in separating mixed waste and baling it. In waste management in supermarkets, logistics companies and large storage areas.

The vertical baler press machine must be maintained regularly. Hydraulic oil change, lubrication of mechanical parts, control of electrical systems and general cleaning operations must be carried out regularly. Maintenance operations ensure the long life and efficient operation of the machine.

Yes, our modern vertical balers are designed with energy efficiency in mind. Energy efficiency modes and automatic shut-down features optimize energy consumption and reduce operating costs.

The noise level of our vertical balers can vary depending on the model, but they are generally designed to operate at a low noise level. In general, they operate at a noise level of 72-74 dB.

Prices of our vertical balers are determined by model, capacity, optional features and customer demands. Pricing is done to offer the most suitable solution for the specific needs of your business.

Some of our vertical baler models can be equipped with portable systems as an option. Our portable vertical baler presses can be easily used in different areas and offer flexible use.

Different sizes of sieves can be used, but this directly affects the capacity.

Our vertical baling presses are available in models with different capacities and features. For example, the DB-5 model offers 5 tons of pressing power, while other models can have 10 tons, 15 tons, 20 tons, 50 tons or 120 tons of pressing power.

.webp)