Modular Structure and Easy Installation

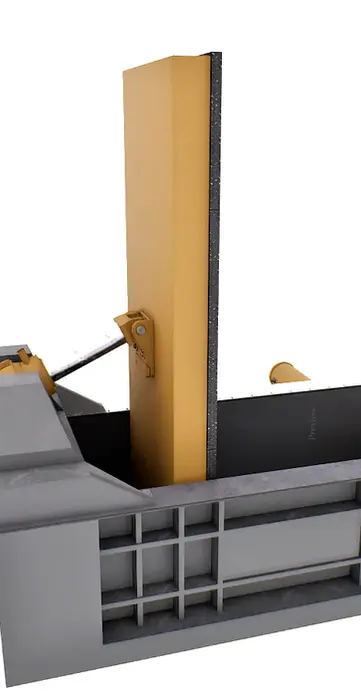

The scrap cutting baler machine provides easy installation in various facilities with its compact structure and modular features.

Advanced Control System

With its programmable control system and real-time diagnostic features, the scrap shear baler increases operational efficiency by providing the user with full control.

High Energy Efficiency

Optimizing energy consumption thanks to its powerful hydraulic system, the scrap cutting baler reduces operating costs.

Easy Maintenance and Long Life

With external adjustable liner plates and easily accessible components, the scrap shear baler offers low maintenance and minimal downtime.

Customizable Cutting and Baling

The scrap cutting baler has the ability to make bales and cuts of different sizes according to customer needs.

Machining Different Types of Metals

Ideal for compressing and cutting various metals such as steel, aluminum and copper, the scrap cutting baler offers a wide range of uses.

Durable Frame Structure

The scrap cutting baler machine provides long-lasting use with its robust and heavy-duty frame structure and works uninterruptedly in difficult conditions.

High Density Compression

The scrap shear baler reduces storage and transportation costs by turning metal materials into high-density bales.

Use of Scrap Cutting Baler in Metal Recycling

Scrap Cutting Baler Machine offers a comprehensive solution for businesses that want to process and recycle heavy and light metal materials. This versatile metal press machine is used to compress scrap into a bale or to prepare it for transportation by cutting it. Among the advantages and features of the scrap cutting baler machine, models such as aluminum press machine, scrap iron press stand out with their wide charging box openings and high tonnage fixed units. Metals such as steel, copper, stainless steel can be processed efficiently with the hydraulic scrap press. Stationary scrap press machines provide dense bales by compressing large volumes of materials with high force. Portable scrap presses are a suitable alternative for processing lightweight and lower force materials.

Scrap cutting baler application areas and performance, models that are effective in breaking down large metals such as casting scrap, pipes, beams and automobiles, perform the process in a short time with a double shaft hydraulic system. Scrap press models provide high volume production with a production capacity of 22 to 30 tons per hour and cut or bale large materials in a short time. The special components and technological features of the scrap cutting baler include durable steel components and side compression mechanism. The air cooler system contributes to the protection of the parts by keeping the oil temperature at a minimum. PLC controlled user-friendly interface and remote control provide easy and effective use.

In terms of safety and efficiency, scrap cutting baling presses isolate the machines with protection barriers during operation and provide safe operation. It increases the stability of operation with automatic cooling system. Diesel engine option provides high performance by providing continuous use even in power outages. Material type, processing volume, charging box size and production requirements are among the things to be considered when choosing a scrap cutting baler. Long-lasting use and easy maintenance features provide low operating costs for businesses. Scrap pressing machines equipped with electric or diesel engine options and hydraulic system increase the recycling efficiency of businesses and also offer cost advantage.

Scrap Shear Baler: Effective Compaction Solution for Bulky Metal Waste

Scrap Cutting Baler Machine is a powerful machine that combines scrap press and scrap baling press functions, specially designed to accelerate the recycling of metal waste. Metals that are reduced in volume and made compact with the metal pressing process are subjected to the pressed metal process and become ready for transportation. Especially by using the scrap cutting baler machine, various types of metals such as steel, copper, aluminum can be processed and reused. These machines work with high pressure thanks to their hydraulic scrap pressing systems, allowing even heavy metals to be easily compressed.

Models such as scrap iron press and aluminum scrap press press large volumes of waste and turn them into small bales with the feature of metal scrap press. Thus, while storage and transportation costs are reduced, compact models such as aluminum press machine provide businesses with an efficient recycling process. Thanks to the features of scrap cutting bale press, metal waste is compressed and becomes portable. In addition, metal press machine and press scrap machines offer businesses high capacity production.

The scrap cutting baler is designed with the high durability required for the press metal process and is produced using quality materials in the scrap press manufacturing processes. Especially, with the top pressing scrap press models, it is possible to easily press even large metal parts. The scrap cutting baler, offered in both portable and fixed models, offers an ideal solution for modern recycling facilities and offers a wide range of options in terms of scrap press machine prices.

Scrap Shear Baler: Effective Compaction Solution for Bulky Metal Waste

Scrap Cutting Baler Machine is a powerful machine that combines scrap press and scrap baling press functions, specially designed to accelerate the recycling of metal waste. Metals that are reduced in volume and made compact with the metal pressing process are subjected to the pressed metal process and become ready for transportation. Especially by using the scrap cutting baler machine, various types of metals such as steel, copper, aluminum can be processed and reused. These machines work with high pressure thanks to their hydraulic scrap pressing systems, allowing even heavy metals to be easily compressed.

Models such as scrap iron press and aluminum scrap press press large volumes of waste and turn them into small bales with the feature of metal scrap press. Thus, while storage and transportation costs are reduced, compact models such as aluminum press machine provide businesses with an efficient recycling process. Thanks to the features of scrap cutting bale press, metal waste is compressed and becomes portable. In addition, metal press machine and press scrap machines offer businesses high capacity production.

The scrap cutting baler is designed with the high durability required for the press metal process and is produced using quality materials in the scrap press manufacturing processes. Especially, with the top pressing scrap press models, it is possible to easily press even large metal parts. The scrap cutting baler, offered in both portable and fixed models, offers an ideal solution for modern recycling facilities and offers a wide range of options in terms of scrap press machine prices.

High Performance Waste Processing in Recycling Facilities with Scrap Cutting Baler

Scrap Cutting Baler Machine Performance and Efficiency

.webp)

High Density Compression

The scrap shear baler reduces storage and transportation costs by turning metal materials into high-density bales.

.webp)

Customizable Cutting and Baling

The scrap cutting baler has the ability to make bales and cuts of different sizes according to customer needs.

.webp)

High Energy Efficiency

Optimizing energy consumption thanks to its powerful hydraulic system, the scrap cutting baler reduces operating costs.

.webp)

Modular Structure and Easy Installation

The scrap cutting baler machine provides easy installation in various facilities with its compact structure and modular features.

Scrap metal shear baler machine allows various metals such as thin metal materials, scrap steel, scrap iron, wire rods up to 5 mm thick to be compressed into rectangular bales. In addition, the metal scrap shear baler machine stands out with its capacity to cut bales into different lengths according to customer requirements, and with these features, it facilitates the storage and transportation of scrap metal. At the same time, it provides qualified furnace charge for metal melting plants and is widely used in waste metal recycling plants and metal melting plants.

The scrap cutting baler offers long-lasting use with its robust frame structure and is designed to provide uninterrupted service for many years. This scrap press machine provides higher side compression forces with its specially developed lidded box structure for superior capture of bulky materials. Thanks to the heavy-duty frame structure, problems associated with cutting thick materials are reduced. The shear blade on the machine offers high cutting efficiency with its superior cutting angle and bolted connection system. This scrap cutting baler, which offers easy maintenance with external pin and guide adjustments, minimizes downtime.

The scrap shear baler provides high baling pressure and density, resulting in higher bale efficiency. Easy maintenance and long life are ensured by external adjustable liner plates, while the metal scrap press is equipped with real-time diagnostics and operational reports. These features allow easy management of the material loading process from start to finish. Our company's scrap metal shear baler provides reliable, long-lasting and high-performance waste processing solutions, ensuring high efficiency in the field of recycling and waste management.

Scrap Baler Cutting Machine Usage Areas

.webp)

Scrap Cutting Baler Machine Technical Specifications

Ürün | Balya (mm) | Ağırlık (kg) | Motor (kw) |

|---|---|---|---|

DB-120 | 1200 X 1100 X 1100 | 800-1200 | 75 |

DB-50 | 1200 X 1500 X 1100 | 250-300 | 11 |

DB-20 | 1000 X 975 X 800 | 130-150 | 3 |

DB-5 | 600 X 435 X 560 | 40-45 | 1,5 |

DB-10 | 735 X 700 X 500 | 60-75 | 2,2 |

DB-15 | 850 X 900 X 800 | 90-100 | 2,2 |

Optional Features

PLC Control System

Remote control

Double Piston Compression System

Cycle Time Monitoring

Mobile Unit Options

Security Cages and Light Curtains

Scrap Cutting Baler Frequently Asked Questions (FAQ)

Scrap shear baler is ideal for compressing and cutting various types of metals such as steel, aluminum, copper, iron. Equipped with scrap press machine and hydraulic scrap press features, this machine has the capacity to process a wide range of metals from thin metals to large volumes of heavy metals.

Scrap cutting baler, with its powerful hydraulic scrap press system, compresses scrap metals into compact bales or cuts them to make them suitable for transportation. It processes metal waste effectively thanks to its high-pressure systems such as press metal and metal scrap press.

Scrap shear baler offers a practical maintenance process with its adjustable lining plates and easily replaceable components. Equipment such as metal press machine and scrap iron press can be used for a long time and efficiently with regular maintenance and control.

Yes, the scrap cutting baler offers both energy saving and high performance with its energy efficient hydraulic scrap press. It reduces costs with energy efficient optimized systems such as the aluminum scrap press.

Scrap shear baler is widely used in areas such as recycling facilities, metal melting facilities, automotive industry and construction sector. This scrap press and metal press machine supports the workflow of enterprises with its wide usage area.

Yes, the scrap cutting baler can be customized according to needs such as charging box dimensions, bale dimensions and engine features. These features provide solutions suitable for the needs of different businesses with scrap press manufacturing and pressmetal.

The scrap shear baler is produced in portable and stationary models. The portable scrap shear baler is ideal for light metals, while the stationary models are suitable for high capacity and powerful compression.

The scrap cutting baler offers safety features such as protection barriers and automatic stop system. These features, designed to ensure safety during the use of press scrap and metal press, provide safe and efficient operation.

Yes, basic operator training is recommended for the scrap cutting baler. The correct use of machines such as the scrap crushing press and the top pressing scrap press is important for occupational safety.

Yes, the scrap cutting baler is usually offered with a one-year warranty. The warranty period can be extended for products such as scrap press machine and metal press machine if necessary.

- Error: empty slot

.webp)