.webp)

Energy Efficiency

Straw pressing operates with low energy consumption, increasing environmental sustainability and reducing energy costs for businesses.

.webp)

Flexible Use

The straw press machine, which has versatile usage areas like a grass press, offers a wide range of usage to agricultural enterprises.

.webp)

Durability and Longevity

Produced with high quality materials, the press straw machine is long-lasting and durable, which ensures that it can be used safely for many years.

.webp)

Security Features

The straw pressing machine is equipped with various safety systems, providing maximum safety during operation.

.webp)

Ease of Use

The straw compression machine offers a solution that operators can easily manage with its user-friendly interface and automatic operating modes.

.webp)

Cost Savings

The straw press machine provides significant cost savings to agricultural businesses, as baled straw takes up less space and reduces transportation costs.

.webp)

Capacity to Process Various Plant Materials

The straw pressing machine facilitates agricultural waste management by baling other plant materials such as grass and alfalfa.

.webp)

Quality Protection

The straw press machine compresses the straw, reducing its contact with air, thus protecting it from external factors and preserving the quality and nutritional value of the straw.

.webp)

Space Saving

Bales compressed with a straw press save significant space during transport and storage, which helps to use storage areas more efficiently.

.webp)

High Efficiency

The straw press machine speeds up the production processes of agricultural enterprises by quickly turning large quantities of straw and other plant materials into bales.

Straw Press Machine: Productivity and Storage Solutions in Agriculture

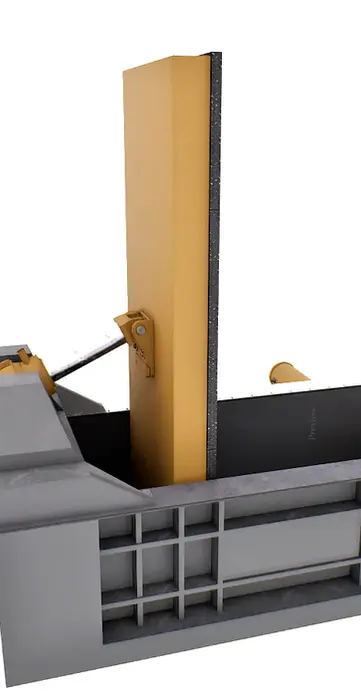

Straw press machine is an effective machine that compresses post-harvest straw and plant residues into bales in the agricultural sector. Straw press produces compact bales by compressing plant materials such as straw, grass, alfalfa. These bales save space during transportation and storage while preserving the quality of the straw. Straw press machine is an important equipment for large farms and agricultural enterprises and increases agricultural productivity.

The straw press machine works with hydraulic systems and allows the straw to be placed in the feed hopper and compressed under high pressure to form bales. The straw pressing machine can work in manual or automatic mode and is very practical to use. Offering varying press power and compression capacity in different models, these machines have the capacity to produce bales of various sizes. The straw compression machine works with hydraulic power options and is used in the compression of all types of agricultural waste.

Straw press machine price may vary depending on model, capacity and technology used. Thanks to security mechanisms, the pressing straw process is carried out safely. The grass press provides the compression of straw, alfalfa and other plant materials and thus offers significant advantages in transportation and storage. Straw press machine is a frequently preferred solution in the agricultural sector and offers high performance in straw pressing and straw compression processes.

Straw Press Machine Advantages: Fast and Effective Baling

The straw press machine increases the efficiency of agricultural enterprises by quickly and efficiently baling large amounts of straw. It offers a much faster and more effective process compared to manual methods. Compact bales produced with the straw press save space during transportation and storage, helping to use storage areas more efficiently and reduce transportation costs.

The straw press machine minimizes the contact of straw with air, which protects the straw from external factors and prevents quality loss. In this way, it preserves the nutritional value of the straw to be used as animal feed. The straw press machine can turn not only straw but also other plant materials such as grass and alfalfa into bales, thus facilitating the management of plant residues.

The straw pressing machine is equipped with various safety features to ensure user safety and offers easy use with its user-friendly interface. The straw compression machine provides more efficient work by reducing labor with automatic operating modes. The straw pressing machine, which has wide usage areas such as grass press, performs agricultural waste management more efficiently and effectively.

Straw press machine price may vary depending on model and capacity. The press machine provides both economic and logistic advantages to agricultural enterprises by offering speed and efficiency during straw operations. Straw pressing process is a modern and environmentally friendly solution in the management of agricultural waste.

Press Straw Machine: The Best Solution for Hay, Grass and Alfalfa

Straw Press Machine Performance and Efficiency

High Efficiency

The straw press machine speeds up the production processes of agricultural enterprises by quickly turning large quantities of straw and other plant materials into bales.

Quality Protection

The straw press machine compresses the straw, reducing its contact with air, thus protecting it from external factors and preserving the quality and nutritional value of the straw.

.webp)

Processing Various Plants

The straw pressing machine facilitates agricultural waste management by baling other plant materials such as grass and alfalfa.

.webp)

Durability and Longevity

Produced with high quality materials, the press straw machine is long-lasting and durable, which ensures that it can be used safely for many years.

Straw press machine plays an active role in many applications with a wide range of usage in the agricultural sector. Straw press provides effective waste management and storage solutions in baling straw to be used as animal feed in animal husbandry, in compressing the excess plant materials after harvest in field crops and in the production of large amounts of straw in large farms.

Straw press machine provides significant advantages in terms of efficiency, cost savings and quality preservation in the agricultural sector. Straw pressing machine provides effective compression and storage of post-harvest plant residues and offers an ideal solution for agricultural enterprises. Straw compression machine can be used in agricultural activities of all sizes, from large farms to small agricultural enterprises.

As MT Makina, we help optimize agricultural processes with our high quality and durable straw press machine solutions. Straw press machine price may vary depending on model and capacity, but it provides cost advantage in the long term by increasing agricultural efficiency. Our machines, which offer flexible solutions for various agricultural applications such as hay press and straw press machine, perfectly adapt to the needs of your business. Straw pressing takes your business to the next level by providing sustainable and efficient waste management in agriculture.

Straw Press Machine Usage Areas: Efficiency and Effective Storage Solutions in Agriculture

.webp)

Straw Press Machine Technical Specifications

Ürün | Pres Gücü (T) | Balya (mm) | Hazne (mm) |

|---|---|---|---|

SP-40 | 40 | 50 X 50 | 1000 X 400 |

SP-50 MOBİL | 50 | 80 X 80 | 1600 X 800 |

Optional Features

Automatic Feeding System

Humidity Control System

Interchangeable Bagging Types

Extra Security Features

Portable System

Production in Different Capacities

Straw Press Machine Frequently Asked Questions (FAQ)

Straw press machine is an agricultural machine that compresses straw, grass, alfalfa and other plant materials after harvest into compact bales. These bales save space in storage and transportation and maintain the quality of the straw.

Our straw press machine can compress various plant materials such as straw, grass, alfalfa, wheat stalks, corn stalks into bales. These machines have the capacity to process different plant residues.

Our straw press machines work with mechanical or hydraulic systems. Plant materials are placed in the feed hopper and are baled under high pressure with a powerful compression mechanism. The machines can work in manual or automatic mode and are easy to use.

It quickly bales large amounts of straw, offering a faster and more efficient process compared to manual methods. Compact bales save space during transportation and storage. Compressed bales prevent quality loss by reducing the contact of straw with air. It can bale a variety of plant materials. It is equipped with advanced security features and user-friendly interfaces.

The maintenance of our straw press machines should be done regularly. Hydraulic oil change, lubrication of mechanical parts, control of electrical systems and general cleaning operations should be done regularly. Maintenance operations ensure long-lasting and efficient operation of the machine.

Our straw press machines work with mechanical or hydraulic power options. In different models, engine power and press power may vary. For example, small-scale machines work with lower power requirements, while large-scale machines require higher power.

Yes, optionally the straw press machine can be equipped with portable systems. Our portable straw press machines can be easily used in different areas and offer flexible use.

Our modern straw press machines are designed with energy efficiency in mind. Energy efficiency modes and automatic shut-down features optimize energy consumption and reduce operating costs.

The prices of our straw press machines are determined by model, capacity, optional features and customer demands. Pricing is done to offer the most suitable solution for the specific needs of your business.

Our straw bale presses are used effectively in a wide range of agricultural applications. Baling straw to be used as animal feed. Compressing and storing surplus plant material after harvest. Effective waste management and storage solutions for farms producing large amounts of straw.

Yes, operator training is required for the correct and safe use of our straw press machines. Training should be carried out in accordance with the machine's user manual and information on safety procedures should be provided.

.webp)